News

Online testing of operating parameters of hydraulic motors using WEBTEC's HPM4030

Webtec Digital Hydraulic Tester HPM4030 is an ideal entry-level product for preventing and diagnosing hydraulic faults. Hydraulic engineers can connect two and three sensors simultaneously, display readings, record data, and export data results to HPMComm software for further analysis. Here we take the on-line test of the operating parameters of the A2FM107 hydraulic motor (used for water pump drive) with the HPM4030 as an example to explain in detail the use of the HPM4030.

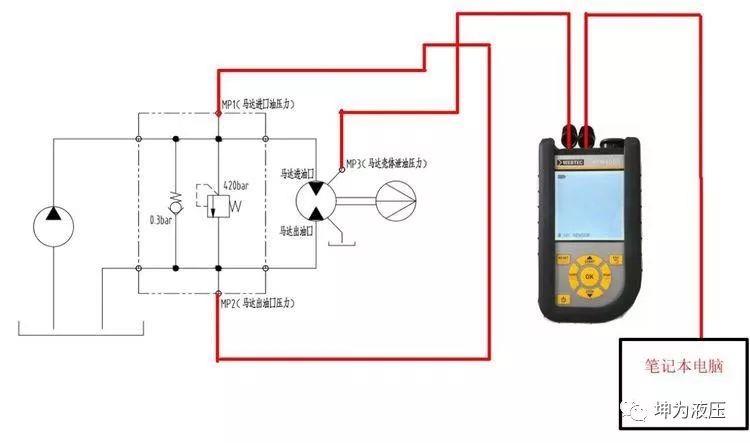

Test principle and wiring diagram

Prepare a set of HPM4030 testers, a laptop, and three pressure taps before starting the test. Then follow these steps to install and test:

1, the table line, sensors and HPM4030 tester connected;

2. Connect the sensor and pressure measuring hose;

3. Connect the 0-600bar sensor to the MP1 pressure port connector, the 0-60bar sensor to the MP2 port pressure connector, and the -1- 16bar sensor to the MP3 port pressure connector according to the connection method of Figure 1. ;

4. Open the HPM4030 tester and open the HPMComm software on the notebook. Set parameters such as pressure and temperature.

5. Start the equipment and let the equipment run for a period of time. Measure the data several times according to different working conditions and save the recorded data to the computer.

After the test is completed, the test data is organized and the test data is analyzed according to different working conditions:

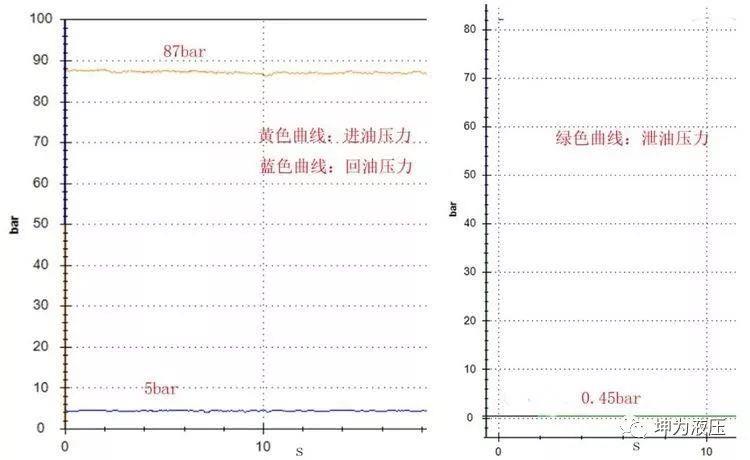

1, idle conditions

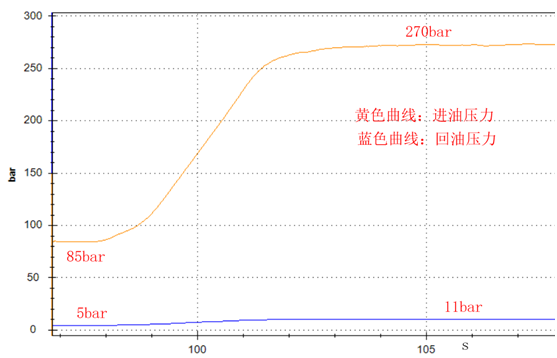

Idling condition test curve

The idling condition is that the engine inlet pressure is 87bar, the outlet pressure is 5bar, and the casing drain pressure is 0.45bar at 710rpm.

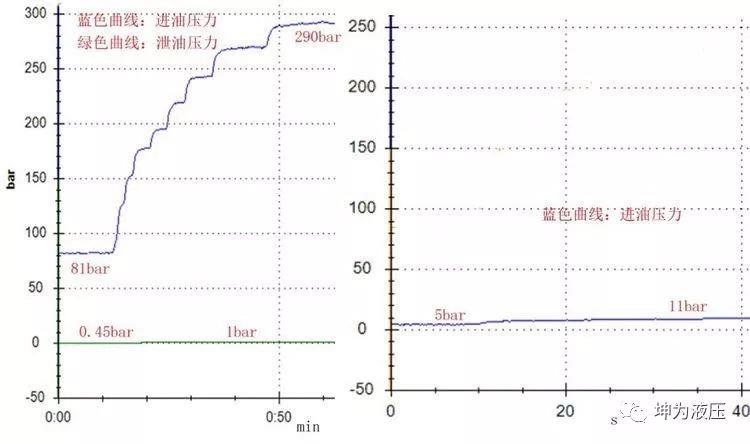

2, idling to full speed conditions

2, idling to full speed conditions

Idle conditions to full speed conditions (710rpm to 1400rpm), motor inlet pressure: 81bar gradually rose to 290bar, outlet pressure: 5bar gradually increased to 11bar, shell drain pressure: 0.45bar gradually rose to 1bar.

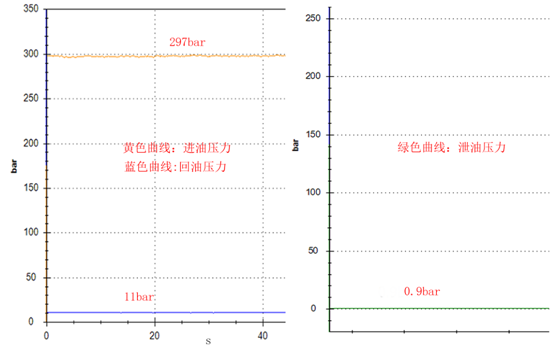

3, full speed operating conditions

Full-speed operating curve

At full speed, the engine inlet pressure at 1400 rpm, motor inlet pressure: 297 bar, outlet pressure: 11 bar, case drain pressure: 0.9 bar.

4, rapid acceleration conditions

The rapid acceleration condition is when the engine is idling, and the speed control knob is turned rapidly to raise the engine to 1400 rpm. According to the curve, this process takes a total of 6 seconds, and the rapid acceleration time is long, which makes the increase in the pressure at the inlet and outlet of the motor more moderate.

5, emergency stop conditions

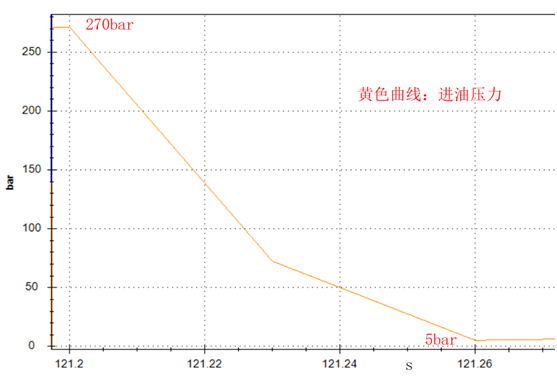

Emergency stop conditions 1

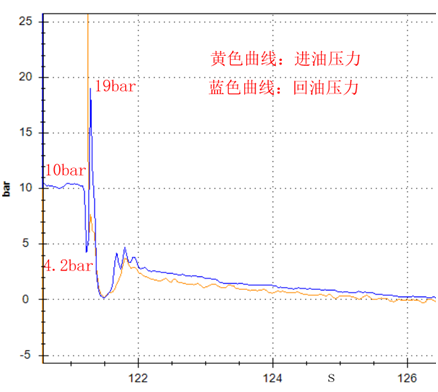

Emergency stop conditions 2

The emergency stop condition is pressing the emergency stop button on the panel, the engine instantly shuts off, and the measured motor inlet pressure and outlet pressure.

In Fig. 6, the inlet pressure of the motor drops from 270 bar to 5 bar within 0.06 s. It can be seen that the pressure drops rapidly after the motor is turned off. As can be seen from Figure 7, the pump continues to operate just because of the inertia. When the pressure difference between the inlet and outlet is greater than the one-way valve opening pressure (0.3 bar), the one-way valve opens and the motor inlet pressure rises from 5 bar to 7.7. Bar. As the pump speed decreases, the inlet pressure falls back to 0.19 bar. Then, as the differential pressure between inlet and outlet decreases and is less than the one-way valve opening pressure (0.3 bar), the one-way valve closes, the inlet pressure rises to 3.7 bar, and finally the inlet pressure slowly drops to 0 bar.

In Fig. 7, the outlet pressure of the motor was instantaneously dropped from 10bar to 4.2bar due to the stalling of the motor, and then the outlet pressure rose back to 19ba due to the inertia of the pump. As the pump speed decreases, the outlet pressure falls back to 0.19 bar. As the differential pressure at the inlet and outlet decreases, the one-way valve closes the outlet pressure and then rises to 4.7 bar. Finally, the outlet pressure slowly drops to 0.1 bar.

From the above on-line testing of the operating parameters of the A2FM107 hydraulic motor using the HPM4030, we can see that the HPM4030 tester is easy to operate and has high test accuracy. It can clearly capture the dynamic changes of the motor pressure every moment. This is common. The pressure gauge is not made, which will promote motor failure analysis and maintenance.

For more information on digital hydraulic tester products and applications, please call: 021-63065298-807/805