News

The difference between digitaHydraulic tester and traditional hydraulic tester

It is well known that to understand the hydraulic performance of hydraulic components and the pressure flow conditions of hydraulic systems, measurement instruments must be used. The use of pressure gauges and mechanical flow meters to measure pressure and flow has been around for hundreds of years. The advantages are low cost, direct readability, and no intermediate links. The limitations are also obvious: (1) It is impossible to observe multiple parameter values at the same time; (2) The dynamic performance is poor (below 10 Hz), and the instantaneous pressure and flow rate values cannot be captured; (3) The process is not performed in a flash. Records cannot be analyzed in depth; (4) Information transmission can only be described in inaccurate language, and text records cannot be generated automatically. The use of digital hydraulic testers can avoid the limitations of traditional pressure gauges and mechanical flowmeters. For example, "Webtec Digital Hydraulic Tester" has the following advantages:

WEBTEC Digital Hydraulic Tester

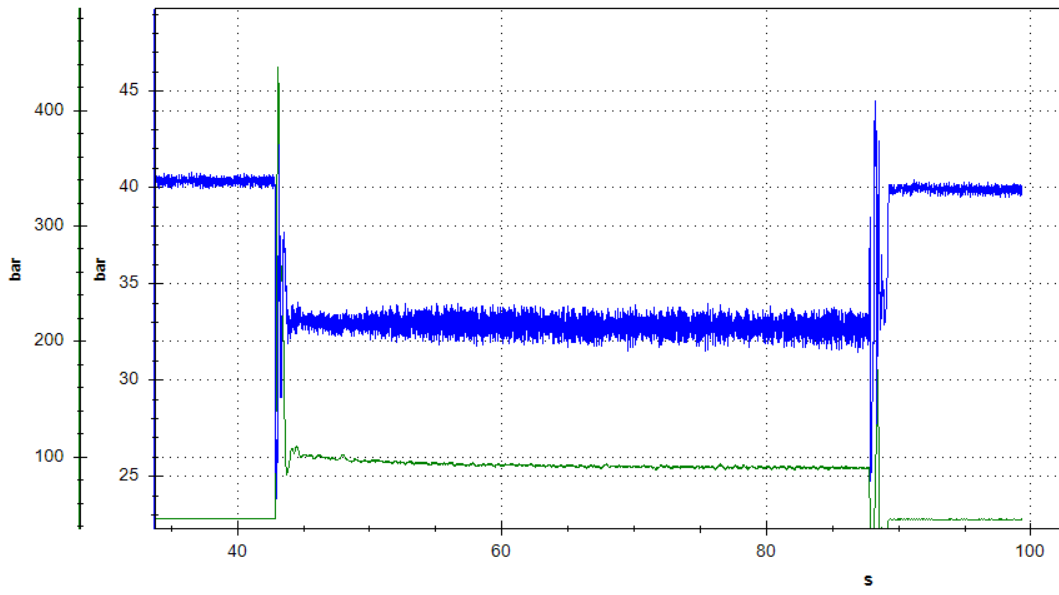

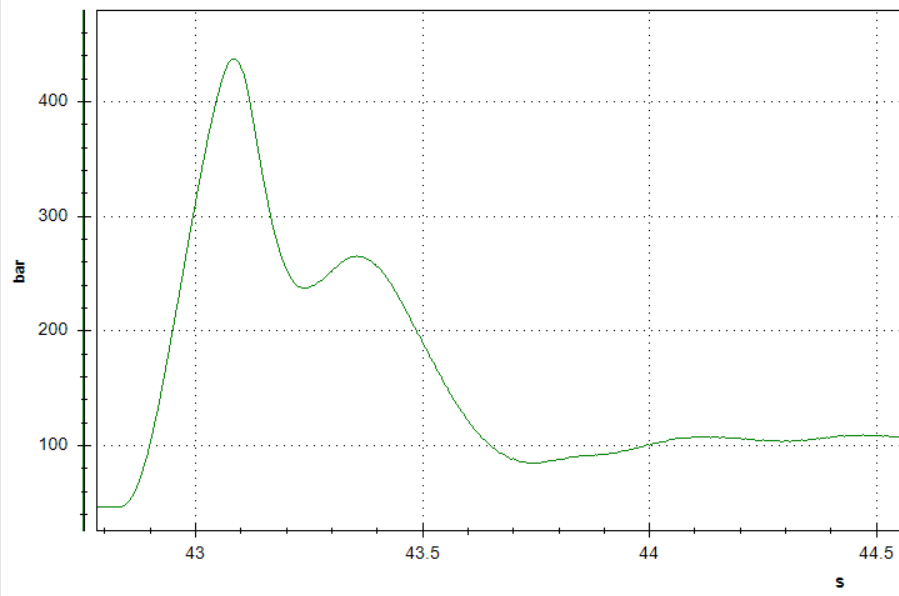

(1) Webtec digital hydraulic tester can measure multiple sets of parameters such as pressure, flow, temperature, power, and volumetric efficiency at the same time. Through the analysis of power and volumetric efficiency, you can debug the pump, motor, and judge the internal wear of the pump and motor. (2) Webtec digital hydraulic tester can configure up to 26 sensors and can measure multiple sets of data at the same time, so that we can analyze the relationship between pressure and flow between different oil lines. The blue curve shown in Figure 2 is a supplement. Oil pressure curve, green curve for high pressure curve; (3) Webtec digital hydraulic tester dynamic performance of the measurement sensor has been up to 2000Hz, enough to seize the pressure transients of the general hydraulic system, and then calmly analyze, short time pressure Impact of the impact on the system and components, as shown in Figure 3 within 0.5s high pressure from 50bar quickly rose to 440bar; (4) the information can be objective, no loss, even in the use of different languages, transfer, exchange, Analyze and discuss that WEBTEC digital hydraulic tester can transmit measurement data online between the device and the computer. We timely save and analyze the data, and solve the problems and timely analysis of components and systems.

Charge and high pressure curves

High pressure curve

In summary, it can be clearly seen that in the hydraulic system troubleshooting, system debugging, Webtec digital hydraulic tester such a modern test instrument has unparalleled advantages than traditional pressure gauges and flow meters. Therefore, the digital hydraulic tester will help us improve system efficiency, system debugging, system troubleshooting, and system optimization.

For more information on digital hydraulic tester products and applications, please call 021-63065298 to 807 or 805.