News

Application of HPM6216 in Power Head of Rotary Drilling Rig

Rotary drilling rig is a kind of construction machine that is suitable for the hole forming operation in the foundation engineering of a building. The power head is used as the core part of the drilling rig. If a failure occurs, it will affect the normal construction. Therefore, we should clarify the work of the power head under different working conditions. In order to avoid damage to the power head due to working under long-term conditions under hidden conditions. The test object is the repaired power head assembly. A pressure test is performed on the working status of the hydraulic components and system of the power head to confirm the synchronization of the motor when the power head is working.

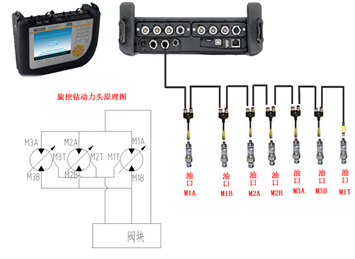

The rotary drill power head of this test adopts three A6VM160HA2 variable motors. Because the motor may be out of synchronization during operation, this test uses HPM6216 under three conditions: forward rotation, reverse rotation, and soil throwing. Simultaneously measure the pressure relationship between the motor ports A and B at the seven oil ports of the motor.

HPM6216 collector and power head

Prepare a set of HPM6216 testers and 7 G1/4 pressure taps before starting the test. Then follow these steps to install and test:

Connect the cable, sensor and HPM6216 collector;

Connect the 0-600bar sensor to the motor working port pressure measuring connector and the -1-16 bar sensor to the pressure measuring connector of the drain port according to the connection method in Fig. 2;

Open HPM6216 collector, set pressure, temperature and other parameters;

Start the equipment, let the equipment run for a period of time, measure the data several times under different operating conditions, and save the recorded data to a computer.

Test schematic

The test data is analyzed after the test is completed. Due to the large number of curves tested, we mainly analyzed the suction and synchronization of the motor.

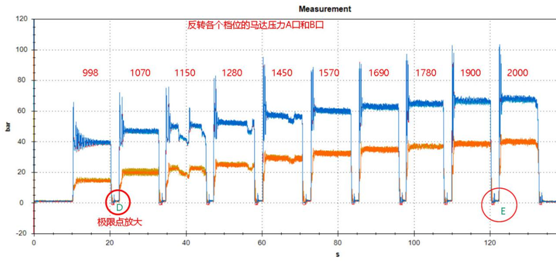

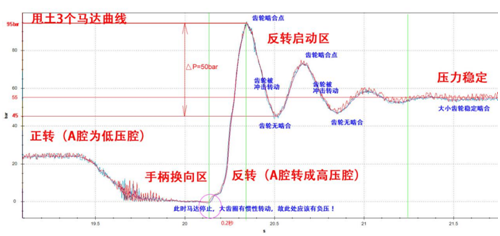

Motor inversion curve

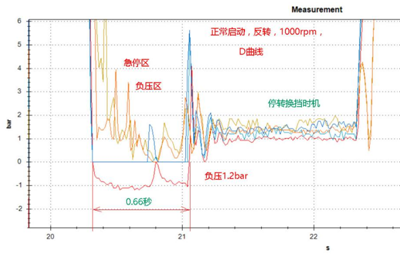

Motor inversion curve D enlarged

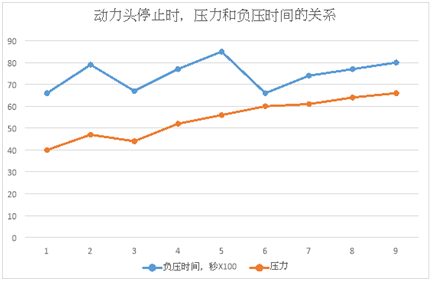

Stop pressure and negative pressure time curve

The two upper fold lines are the pressure at which the motor stops and the duration of the negative pressure at the oil port after the stop. For comparison, the time unit used is increased by 100 times and compared with the pressure value. We can roughly conclude that the pressure at the moment of stopping is directly proportional to the negative pressure after stopping. In fact, the motor pressure at the time of stopping is also proportional to the rotation speed (or moment of inertia) when the motor is under load. The fold line above us also represents the relationship between the rotation speed and the duration of negative pressure at the time of stopping. It shows that the rotational speed of the power head is high, and when the load is large, the damage of the hydraulic motor is greater.

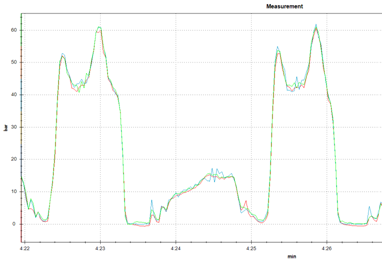

Soil transfer curve curve

Dumping soil condition motor pressure curve

After the curve is enlarged, it can be seen that the red curve represented by the motor No. 2 has a lower pressure and flatness curve under continuous swinging soil conditions. Therefore, the synchronism of the three motors is problematic, the red motor runs slower, the motor is not fully synchronized, and the motor 2 is in a dragged state during operation.

Through the above curve analysis, we can clearly see the working status of the power head at this time, so we can detect the working performance of the power head at any time by using the HPM6216 tester, and provide a reliable basis for daily maintenance and maintenance.

From the above tests on the power head of the rotary drilling rig, we can see that the HPM6216 tester is not only simple to operate, but also accurate and accurate. Through the analysis of the test data, we can easily find and solve problems in the hydraulic system.

For more information on digital hydraulic tester products and applications, please call 021-63065298 to 805 or 807.