News

How to use HPM4030 to detect the suction of hydraulic system

Suction will seriously affect the performance of hydraulic system and components, cause system vibration and abnormal sound, reduce the efficiency of hydraulic components, and shorten the service life greatly. So, how does the air suction happen? What are the effects on the hydraulic system and the components?

Air suction, from the name point of view is the hydraulic element inhaled air, many small partners think that the air is inhaled by inhaling air because of poor sealing. In fact, the air may be inhaled from outside the system (not well sealed) and may be produced by low oil absorption pressure in the oil liquid (cavitation). The species is caused by insufficient oil filling (cavitation). The concept of suction is mostly for pumps, motors, cylinders and other power or executive elements.

Cavitation, when the pressure of a liquid liquid is lower than the pressure of air separation, the air dissolved in the liquid will free out and produce a large number of bubbles in the liquid. This phenomenon is called "gas hole". Therefore, it is necessary for the small partners to see that not only the pump, motor, oil cylinder and other power or executive components will occur cavitation, for the valve and other control elements will also occur cavitation (as long as a certain pressure is lower than the air separation pressure).

The name of cavitation is quite appropriate. The literal understanding is that "gas" corrode the metal surface. In fact, cavitation is accompanied by a series of physical and chemical changes. First, air suction or cavitation occurs in the oil to produce bubbles. These bubbles reach high pressure and are adiabatic, collapse rapidly, and produce very high temperature and impact pressure locally. On the one hand, it causes local fatigue of components. On the other hand, it causes oil deterioration and chemical corrosion to components. Therefore, many small caves that cause erosion, spalling or honeycomb (or sponge like) surfaces of components.

The form of suction pressure is negative pressure. We usually don't detect it with pressure gauge. At this point we need to use professional equipment to measure the suction pressure in the hydraulic system, and the webtec HPM4030 data collector just meets all of our requirements. HPM4030 can detect pressure, flow rate, speed and temperature. The scanning speed is up to 1ms, which can detect pressure below 0bar. Here we will illustrate with an example.

HPM4030 Tester

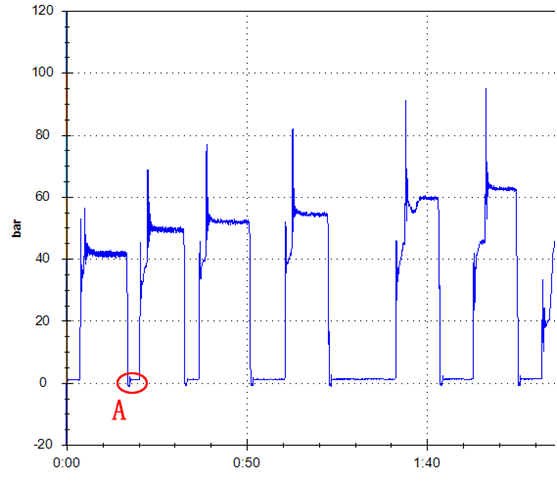

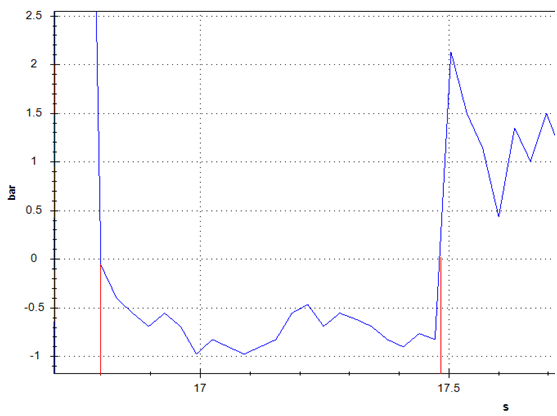

Figure 2 shows the working pressure curve of the forward rotation of the power head motor measured with the HPM4030. From the curve, it can be seen that the motor has negative pressure at the start and stop phases. Figure 3 is an enlarged view of point A in Figure 2. It can be seen from the figure that the negative pressure duration of the motor is 0.7 s.

Power head motor forward working pressure curve

A point enlarged graph

From the above data curve analysis, it can be seen that the negative pressure generated due to the vacuum is present. If the pressure gauge is used to detect it, it is often undetectable, which will leave the hydraulic system with safety hazards. Using WEBTEC test equipment test, through the analysis of the test data, we can easily find the air suction problem in the hydraulic system, and then through effective measures to prevent, so HPM4030 tester is a necessary test tool for hydraulic engineering .

For more information on digital hydraulic tester products and applications, please call 021-63065298-807/805.